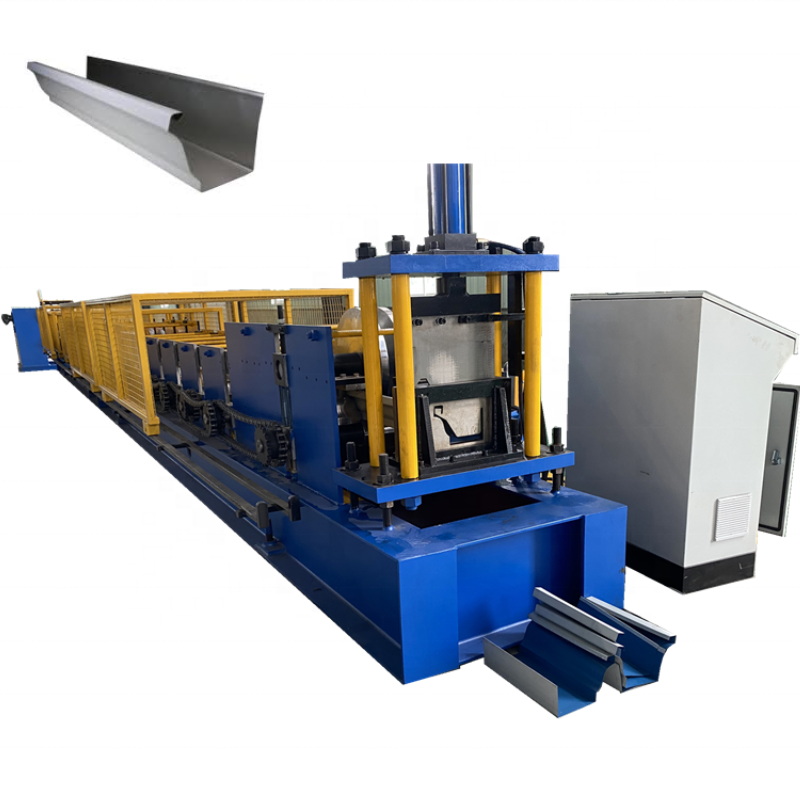

Metal Rain gutter Roll Forming Machine is designed to make the gutters which are attached to the roof edges and used to draw water down and away from the house and its foundation. Most gutters consist of sections of gutter, drop outlets and downspouts. Gutters can be constructed out of aluminum, copper, galvalume, galvanized steel, copper penny aluminum, freedom gray copper, weathered zinc, copper plus, designer copper aluminum, lead coated copper, paint grip steel.

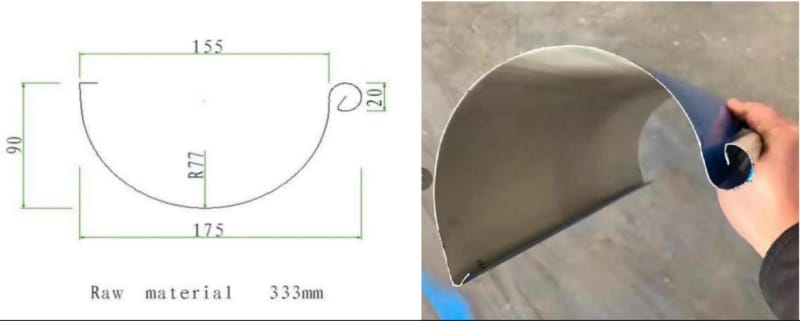

Here are the drawing profile we made before for your reference,we also support customization as customer's request.

The components of the whole production line of Metal Rain Gutter Roll Forming Machine:

1.Manual/hydraulic decoiler

2.Main roll former

3.Hydraulic cutting system

4.PLC control station

5.Product receive table

The technical specifications of the Metal Rain Gutter Roll Forming Machine:

Part 1:Manual decoiler

- Suitable coil width:max 500mm

- Suitable coil inner diameter:450-550mm

- Capacity:max 3 tons

- With braking system

Part 2:Main Roll former

- Main frame:350H steel welded

- Middle plate:18mm thickness

- Shaft diameter:70mm

- Shaft material:45# steel with heat treatment

- Roller material:45# steel with quenched treatment

- Roller station:18 stations

- Motor power:5.5kw

- Transmission:By chain

Part 3:Hydraulic cutting system

- Cutting type:Hydraulic automatic cutting

- Hydraulic power:4kw

- Hydraulic oil:46# hydraulic oil

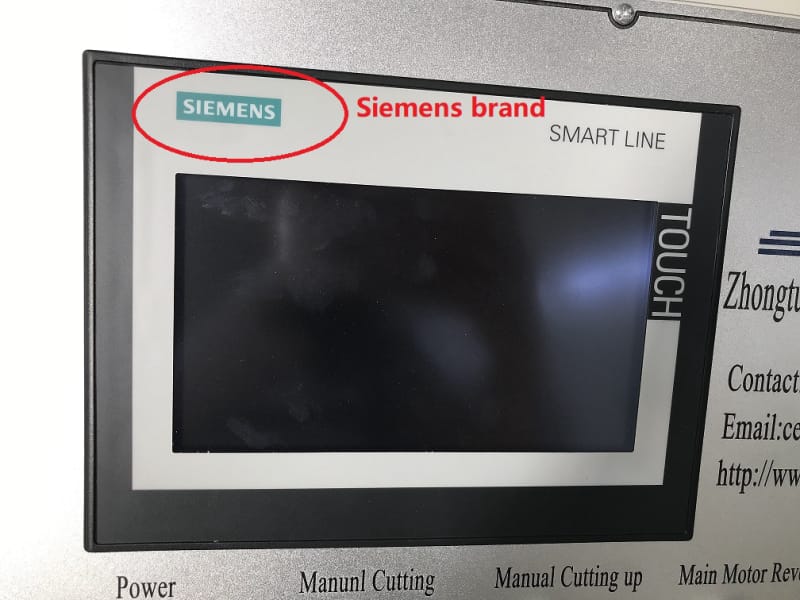

Part 4:Control station

- Control system:PLC

- Function:Control the length,quantity,batch and speed

- Screen:Touch screen

- Electric brand:Delta,Siemens and Schneider

5.Product receive table

- Type:Uppowered roller type

- Length:3 meters

- Quantity:1 set

Metal rain gutter roll forming machine video:

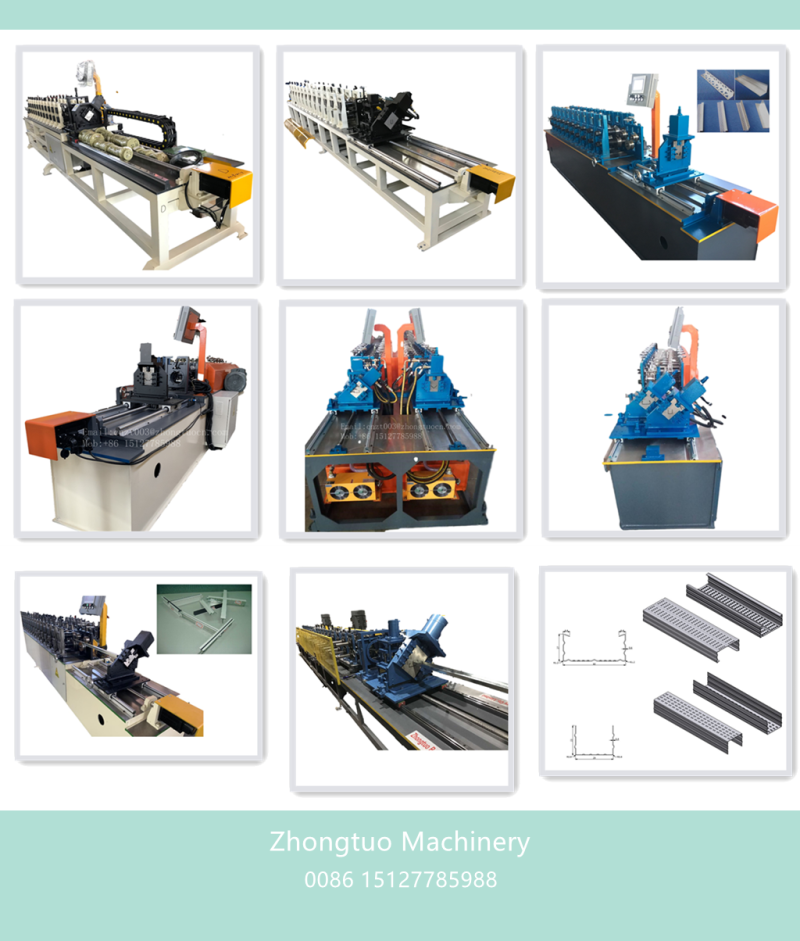

Related roll forming machines:

Recommanded roll forming machines:

No Comment

You can post first response comment.