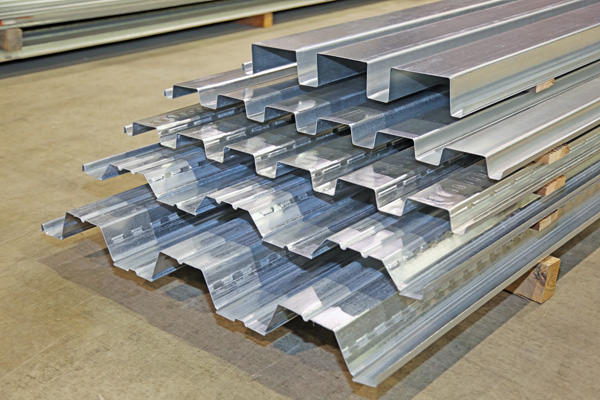

The metal floor deck roll forming machine produced by Zhongtuo is a device used for producing floor decks, mainly used for the production of floor decks in the construction industry. The metal floor deck roll forming machine uses roll cold bending technology to process galvanized steel plates into open type floor support plates, which usually have V-shaped, U-shaped, trapezoidal or similar waveform cross-sections. This type of floor decks can not only be used as a template, but also for various other purposes.

Characteristics and application scenarios:

- Light weight and high strength: Metal floor decks have the characteristics of light weight but high strength, and can withstand large loads.

- Simple and fast construction: Due to its convenient assembly and fast construction speed, it can significantly improve construction efficiency.

- Good seismic resistance: Metal floor decks have excellent seismic performance and are suitable for various building structures.

- Neat and beautiful appearance: The appearance is neat and beautiful, which can enhance the overall aesthetics of the building.

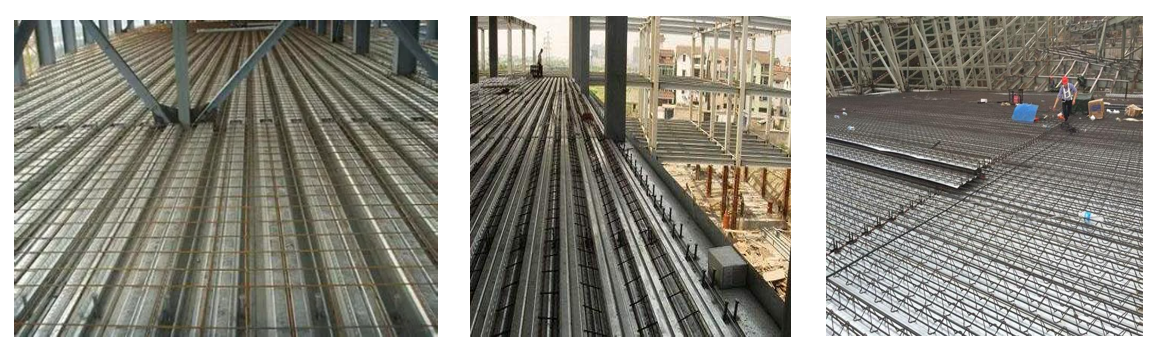

Metal floor decks are widely used in industrial plants and warehouses, and their unique design allows pipelines, wires, and other facilities to easily pass through, saving installation time and costs. The metal floor decks adopts high-strength steel and a unique opening design, which has excellent bearing capacity and stiffness, can withstand large loads, and effectively resist deformation and vibration.

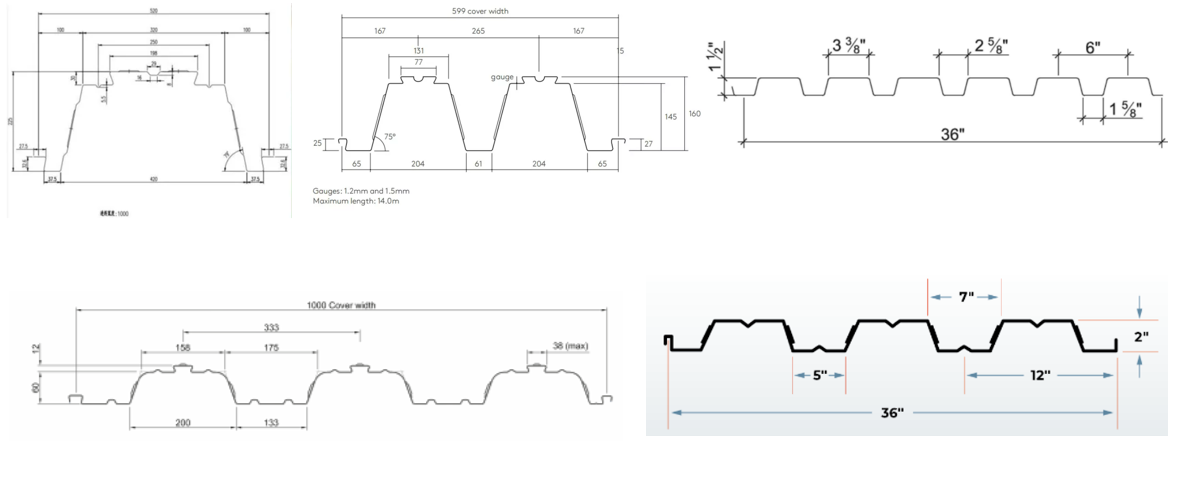

Pattern diagram:

Main components:

Item

Description of Item Unit Quantity 1 Hydualic decoiler set 1 2 Main roll forming machine set 1 3 Hydraulic Cutting system set 1 4 PLC control station set 1 5 Product receive table set 1 6 Spare parts set 1 Product Attributes :

Size of main partabout 15000 х 1850 х 1500 mm(as your requirement)Weight of main partabout 6tProcessing material235 MpaMaterial thickness0.3-1mmInput material width1220mmVoltage380 v 50 hz 3 phase or as requestFrame400 H beam steel weldedRoller fixerMiddle plate (thickness 20mm)Drive modeas your requirementMaterial of rollersGcr15 quenching treat HRC58-60Material of shafts45# steel precision-machinedDiameter of shaftsφ 95 mmNumber of rollersas your requirementDrive motor powerHydraulic unit motor power 7.5kWForming speed0-15 m per minuteProducts Display:

The working video of the product is available for you to watch:

No Comment

You can post first response comment.