Machine operation video:

Tr4 Roof Tile Making Machine Trapezoidal Roofing Roll Forming Machine

Tr4 Roof Tile Making Machine Trapezoidal Roofing Roll Forming Machine is mainly used for producing trapezoidal roof tiles for building roofs. This type of roof tile has good waterproof, weather resistance and aesthetics, and is widely used in the production of roof tiles in the construction industry, especially in the production of roof covering materials for industrial park buildings, factory buildings, logistics warehouses, private residences and other buildings.

Equipment features:

- High degree of automation:

usually fully automatic or semi-automatic equipment, which can automatically complete the processes of raw material feeding, forming, cutting, etc., improving production efficiency. - Good molding effect:

Through a series of rollers and molds, the metal sheet is gradually molded into the desired trapezoidal roof tile shape, with high molding accuracy and stable product quality. - Widely applicable materials:

can process galvanized steel, PPGI and other materials, with material thickness generally between 0.3-0.8 millimeters. - Strong customization:

Roof tiles of different widths, lengths, and shapes can be customized according to customer needs to meet the design requirements of different buildings.

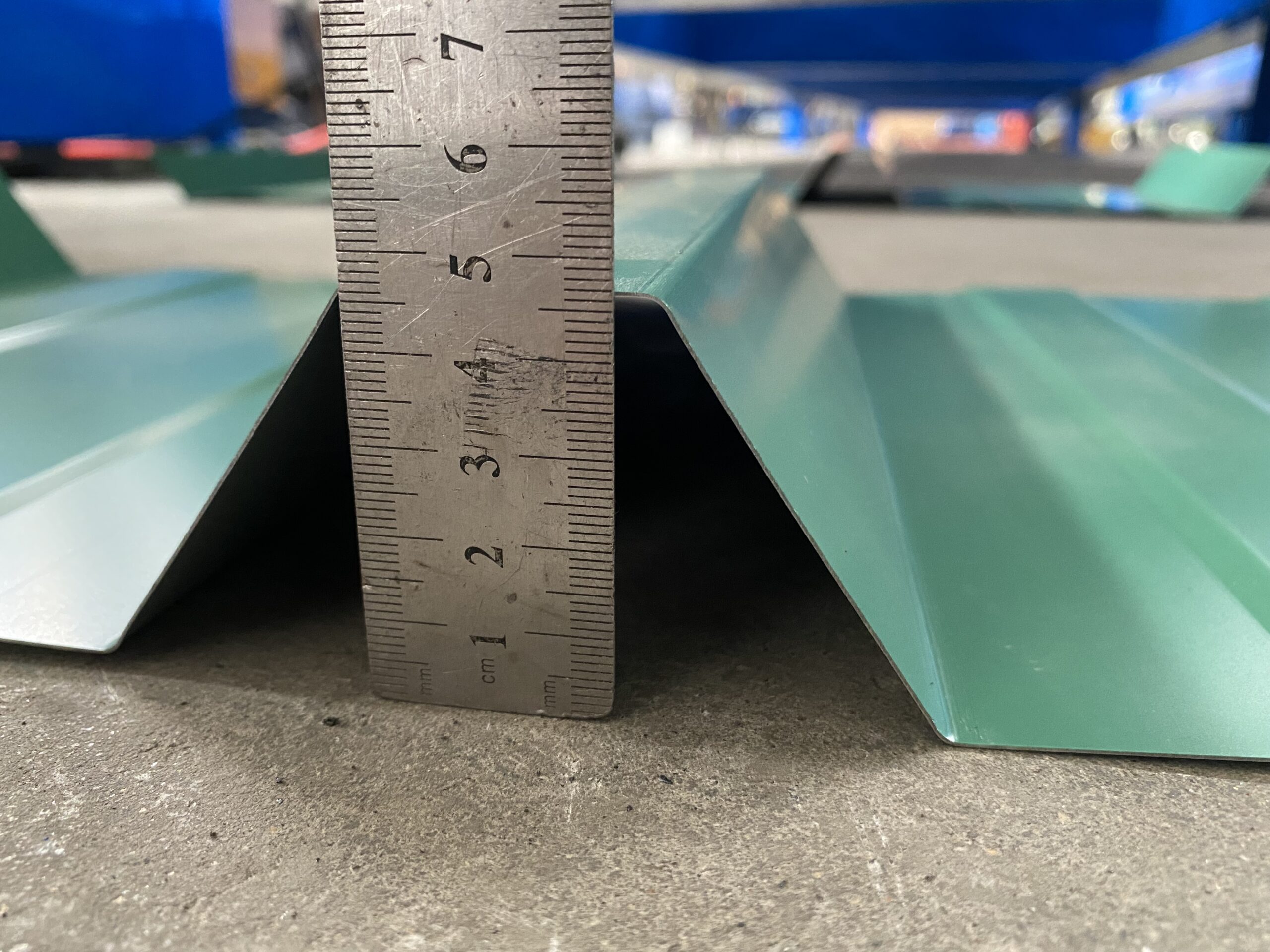

Finished product accuracy test image:

The technical specifications of the Tr4 Roof Tile Making Machine Trapezoidal Roofing Roll Forming Machine:

1.Formed MaterialPPGI,GI,AIThickness:0.3-0.8mm Width:1000mm/1250mm(customized)2.DecoilerHydraulic automatic decoilerManual decoiler(will give you as free)3.Main bodyRoller station18 rows(As your requirement)Diameter of shaft80mm solid shaftMaterial of rollers45# steel, hard chrome plated on the surfaceMachine body frame350 H steelDriveChain transmissionDimension(L*W*H)9500*1600*1600(customize)Weight6.5T4.CutterAutomaticcr12mov material, no scratches, no deformation5.PowerMotor Power5.5KWHydraulic system power5.5KW6.Voltage380V 50Hz 3PhaseAs your requirement7.Control systemElectric BoxCustomized(famous brand)LanguageEnglish(Support multiple languages)PLCAutomatic production of the whole machine. Can set batch, length, quantity, etc.18.Forming Speed15-20m/minThe speed is adjustableMachine photos:

No Comment

You can post first response comment.