Main function:

- Production of synthetic resin tiles:

The steel glazed roofing sheet making forming machine can produce synthetic resin tiles, which have excellent weather resistance. Even under long-term external conditions such as sunlight exposure, temperature changes, wind and rain, there will be no fading, discoloration, cracking, or strength reduction.- Production of PVC glazed tiles:

This machine can also produce PVC glazed tiles, which have stable performance, do not fade, are resistant to long-term exposure to sunlight, moisture, cold and other environments, and have strong physical strength and fire resistance.Characteristics and application scenarios:

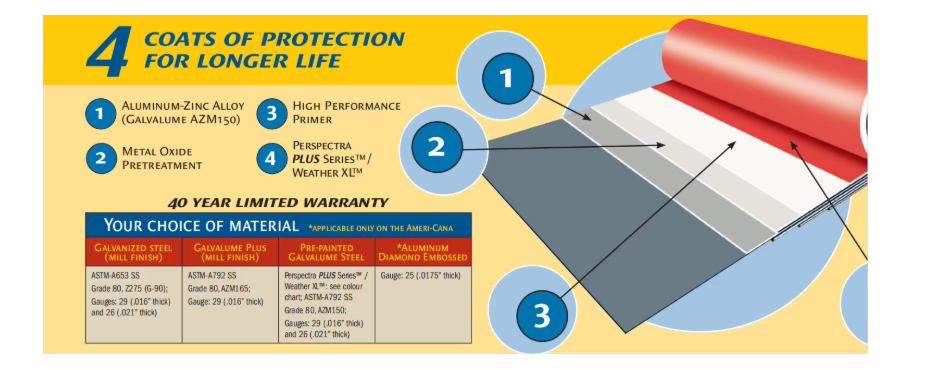

1.Weather resistance and color retention:

The laminated glazed tile adopts three-layer co extrusion technology, with weather resistant engineering resin selected for the surface layer, PVC for the middle layer, and a weather resistant resin wear-resistant layer for the bottom layer, ensuring the product's long service life and good color retention.

2.Anti corrosion performance:

Coated glazed tiles can maintain their performance in highly corrosive environments such as acid, alkali, and salt, making them particularly suitable for roofs in coastal areas and corrosive chemical plants.

3.Fire resistance performance:

The fire resistance of laminated glazed tiles reaches B1 level, and they are not easy to burn. Even under high temperature, they are difficult to catch fire, and the combustion stops immediately after the fire source is removed.

4.Wide applicability:

Suitable for sloping roofs with cast-in-place concrete slabs as the structural base and sloping roofs with purlin systems, suitable for multi story or low rise residential buildings, park buildings, long corridors in public places, etc.

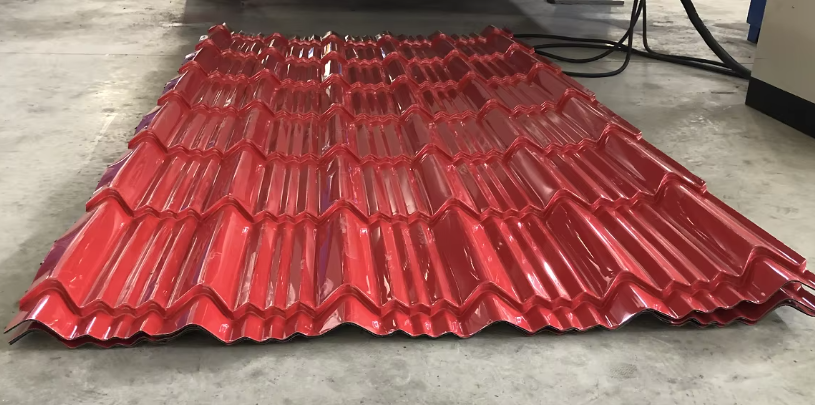

Finished product image:

Product Attributes :

Products Display:

Here is the working video of this machine for everyone to watch:

No Comment

You can post first response comment.