The glazed tile roll forming machine driven by a gearbox is an equipment used for producing glazed tiles, mainly composed of a feeding platform, a forming host, a forming and shearing device, a hydraulic station, a computer control system, and other parts. Its characteristics include small size, light weight, easy mobility and transportation, and small space occupation; One machine is versatile. By selecting and using the corresponding machine head, different varieties and specifications of bricks and tiles can be produced to meet market demand; Using less power, saving energy consumption, and reducing production costs; Reduce labor force, lower labor intensity, and improve labor efficiency. Gearbox driven glazed tile roll forming machines are widely used in various building scenarios, including decoration and construction of roofs, walls, and other buildings. They have the advantages of diverse colors, good surface gloss, corrosion resistance, acid and alkali resistance, aging resistance, good impact resistance, thermal insulation, sound insulation, etc.

Main function:

- Automated molding:

The gearbox glazed tile machine can quickly process raw materials (such as colored steel plates, aluminum alloys, etc.) into the shape of glazed tiles through the step-by-step pressing of multiple rollers. This automated molding method greatly improves production efficiency. Compared to traditional handmade glazed tiles, its production speed can reach 5-20 meters per minute, which can meet the needs of large-scale industrial production.

- Enhance waterproof performance:

Machine produced glazed tiles can ensure a tight fit between tiles during the molding process, improving the waterproof performance of tiles. By precise compression molding, the surface of the tiles becomes smoother, reducing the possibility of rainwater infiltration.

- Improve durability:

In the process of automated production, the material and structure of glazed tiles are more uniform, which improves the durability and wind resistance of the product. This type of glazed tile can better resist the erosion of harsh weather and has a longer service life.

- Wide range of applications:

The glazed tiles produced by the gearbox glazed tile machine are suitable for various building scenarios, including personal residences, villas, industrial plants, park and square buildings, and ancient building restoration. Its products not only have good decorative effects, but also meet practical functions such as waterproofing, insulation, and thermal insulation for buildings.

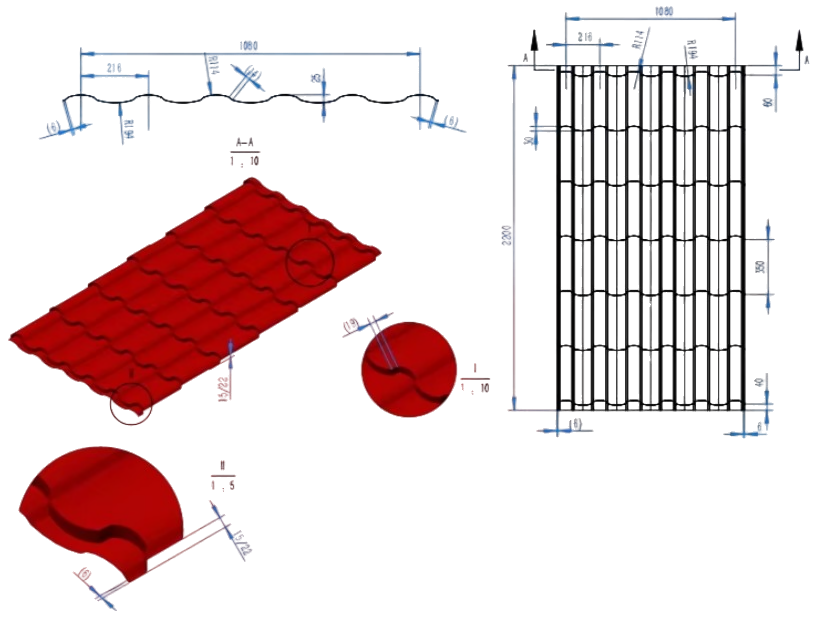

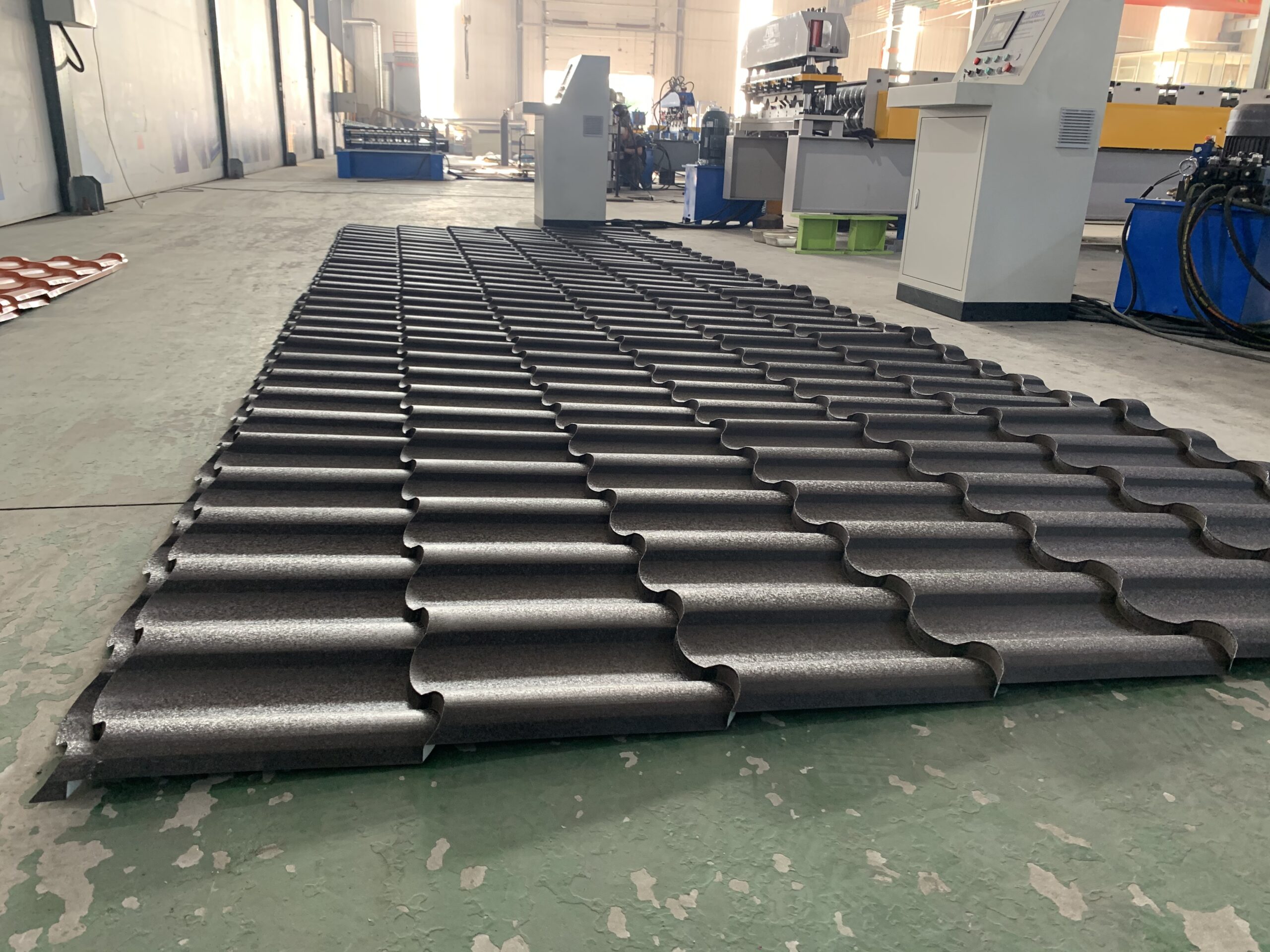

Finished product image:

Main components:

No.

Name

Unit

Quantity

Part 1

5ton manul decoiler

set

1

Part 2

Main roll forming machine

set

1

Part 3

PLC control station

set

1

Part 4

hydraulic system

set

1

Part 5

3M auto stacker

set

1

Part 6

Spare parts

set

1

Product Attributes :

Feeding device the platform width is adjustable by hand wheel, have the bearing inside to protect the edge of the steel sheet. Rolling shaft Shaft Material: 40 Cr STEEL Shaft diameter: 80 mm Tempering treatment, prevent deformed and improve the hardness Roller Roller material: High grade 45# steel Chromed treatment (Chrome thickness:0.05 mm), make the rollers surface more smoothly, improve the hardness and prevent abrasion, anti corrosion increase of service life Rolling station Rolling number: 14 stations for profile Rolling type: separate rolling design concept, it can release internal stress from the sheets, then the sheet will be in good shape and high precision. Work speed 0-6 m/min Machine structure Iron casting Vertical arch frame structure Machine basic frame Hot rolled H-beam We will make diagonal bracing inside the frame, to strength the structure and keep the whole plate in same horizontal plane After the whole welding, vibration is used to weld the stress. After large-scale planer machining, the horizontality and rigidity of the frame are ensured. Bearing Chinese famous brand Harbin Work power 5.5 kw servo motor Roller spacer treatment Electroplate (chromed) Safety cover 1 set Transmission Gear box transmission(bevel gear inside) Advantage: can improve the speed directly after cutting Here is the working video of this machine for everyone to watch:

No Comment

You can post first response comment.