Below is a work flow video for you to watch:

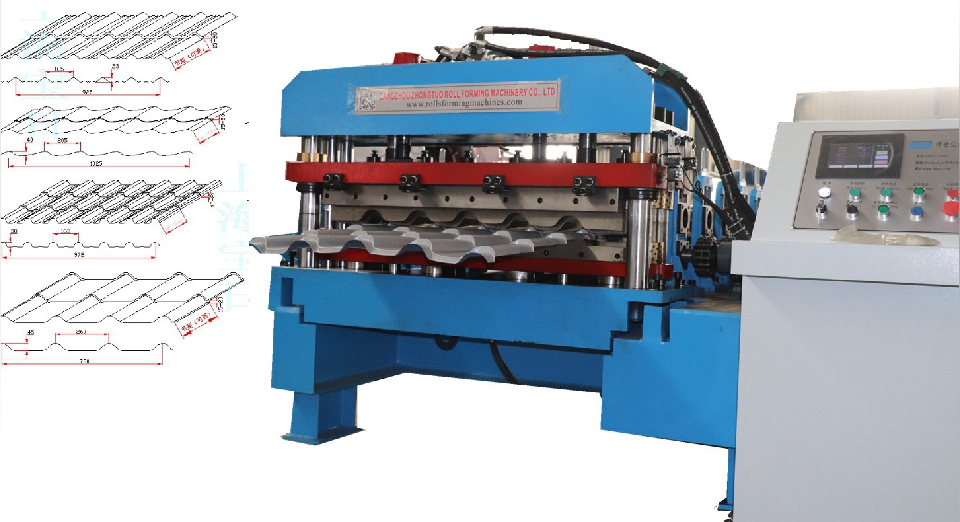

Product Attributes :

1.Formed Material | PPGI,PPGL,AI,Etc. | Material Thickness:0.4-0.6mm | ||

2.Decoiler | Hydraulic decoiler(optional) | Manual decoiler(will give you as free) | ||

3.Main body | Roller station | Due to your requirement profile | ||

Diameter of shaft | Due to your requirement profile | |||

Material of rollers | High Grade 45# Forged Steel, hard chrome plated on the surface(Chrome Thickness:0.05 mm) | |||

Machine body frame | Due to your requirement profile | |||

Drive | gearbox transmission | |||

Dimension(L*W*H) | Due to design | |||

Weight | Due to design | |||

4.Cutter | Automatic | cr12mov material, no scratches, no deformation | ||

5.Power | Motor Power | 7.5KW(normally) | ||

Hydraulic system power | 4.5KW | |||

6.Voltage | As your requirement | As your requirement | ||

7.Control system | Electric Box | Customized(famous brand) | ||

Language | Support multiple languages | |||

PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |||

Product Description:

The glazed tile roll forming machine is a specialized equipment used for producing glazed tiles, which can process metal sheets (such as color steel plates, aluminum plates) or composite materials into glazed tiles with certain shapes and decorative effects. The products produced by it have the characteristics of beautiful appearance, antique elegance, exquisite and unique design, and durability. They are widely used in garden style factories, tourist scenic areas, pavilions, hotels, villas, exhibition halls, resorts, families and other buildings for roof and wall decoration, as well as simple steel shed roof production.

Equipment features:

- Efficiency: It can achieve continuous production, greatly improving production efficiency and meeting the needs of large-scale production.

- Accuracy: High precision processing technology ensures that the tiles produced have precise dimensions and uniform texture.

- Safety: Equipped with various advanced safety protection devices, effectively reducing operational risks.

- Reliability: Through strict quality control and testing, it demonstrates excellent stability and reliability.

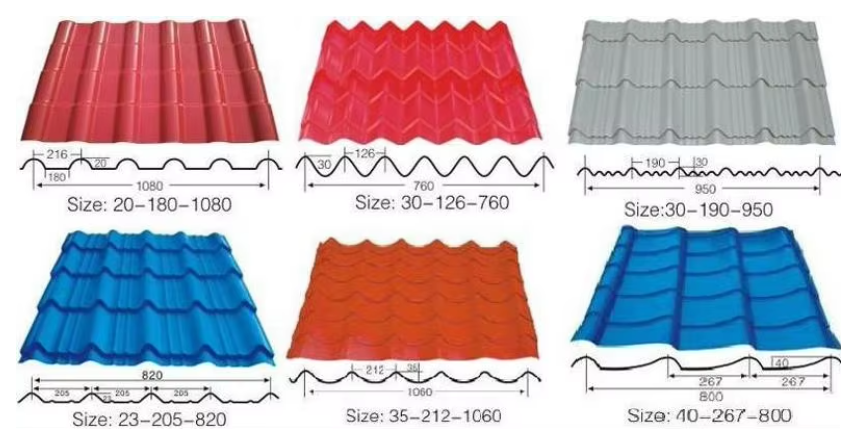

- Multifunctionality: By changing molds or adjusting parameters, different shapes and specifications of glazed tiles can be produced.

- Energy saving: using less power, saving energy consumption, and reducing production costs.

Application scenarios:

- Roof decoration:

used for roofs of garden style factories, tourist attractions, pavilions, hotels, villas, and other buildings. - Wall decoration:

used for decorating building walls to enhance the aesthetic appearance of the building. - Outdoor decoration:

used for outdoor decoration in exhibition halls, resorts, homes, and other places

Products Display:

No Comment

You can post first response comment.