描述

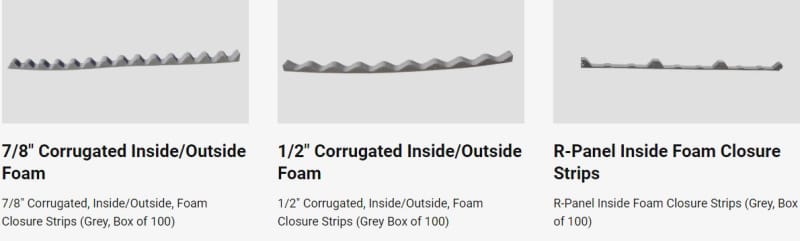

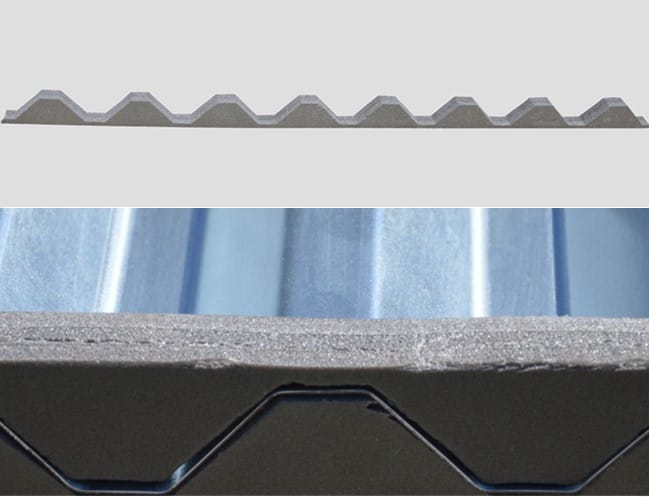

What is Outside Foam Closure Strips

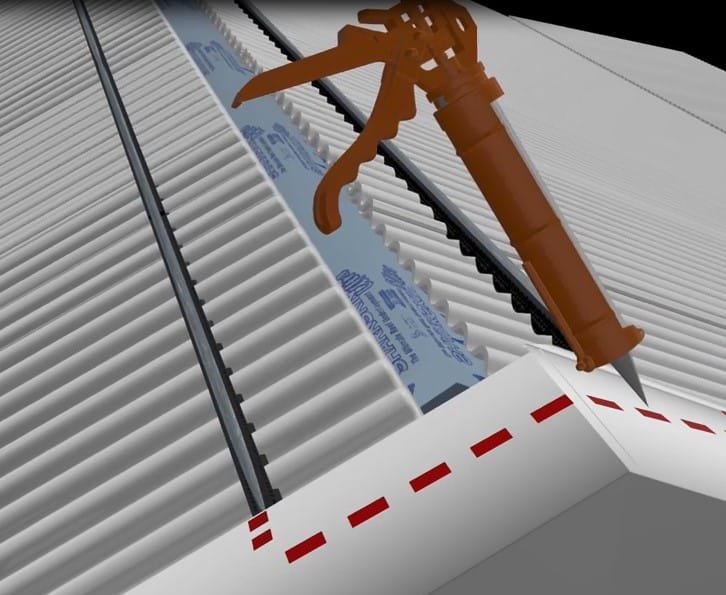

Outside foam closure strips seal the gaps of the outer r panel. This helps to maintain weather-tightness and to decrease moisture and insects from getting inside or beneath the raised portions of roofing panels.

Features & Benefits of Foam Closures

Durable – Resists a wide range of temperature extremes and blocks vapor transmission. Does not shrink, bleed, dry out or dissolve when exposed to extreme weather and UV condition. Does not absorb moisture and is highly resistant to most chemicals.

Versatile –These flexible and lightweight closures are designed to perform in your particular building environment and are available in a variety of widths to meet a wide range of customer specifications.

Sound Absorbing - Reduces noise migration by filling in the gaps where the corrugated metal roofing panels meet the support wall providing a virtual acoustic barrier from outside noise.

Snug Fitted– Our foam closures offer an interlocking dovetail design and are weather tight to help seal out wind, water, birds, and noise.

Based on our market experience, two kinds of foam materials are the regular choice for making metal roof foam closure strips. They are closed cell EVA foam and cross linked Polyethylene foam.

The two kinds of materials are both closed cell foam. They are both excellent at water and moisture resistance, also good cushioning and sealing performance. Comparison between two of the foam materials, Polyethylene foam has better flexibility and resistance. But the drawback for them to make roof closure strips is the original PE foam sheet thickness is 10 mm. But the foam closure strips is around 30 mm thick. In order to have a 30 mm thickness, the Polyethylene foam need to be laminated together with 3 layers. This takes more fabrication process also higher cost. On the other hand, EVA foam has workable cushioning ability also they are able to be fabricated in up to 100 mm thick, which is much enough for making metal roof foam closure strips.

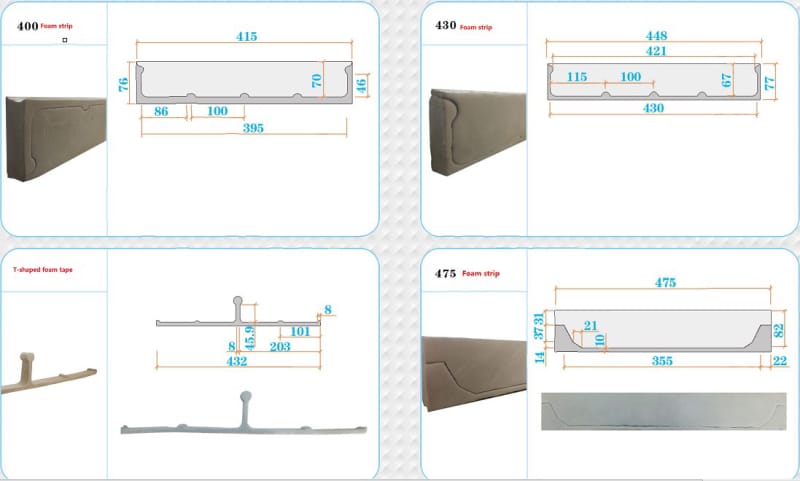

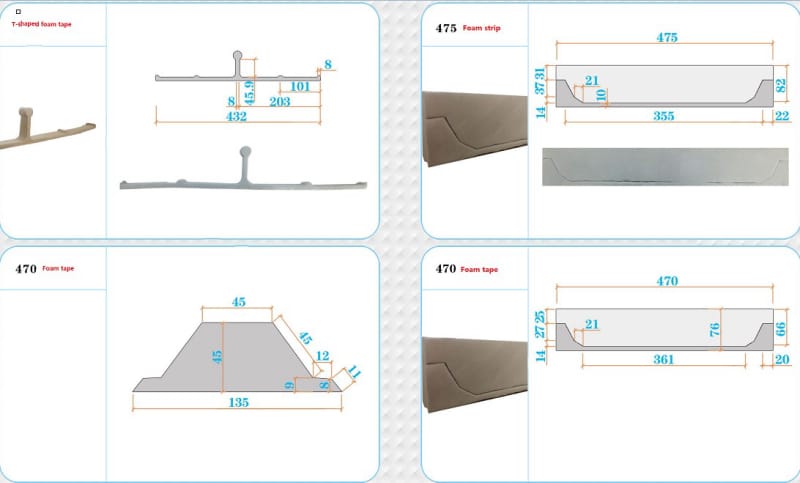

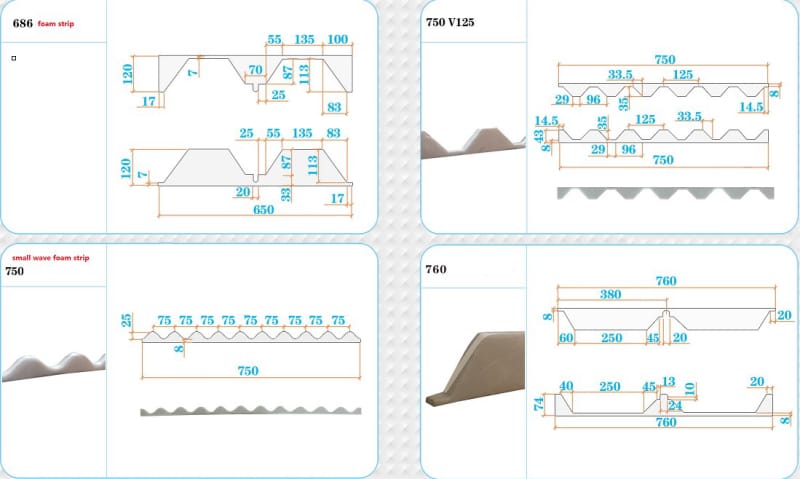

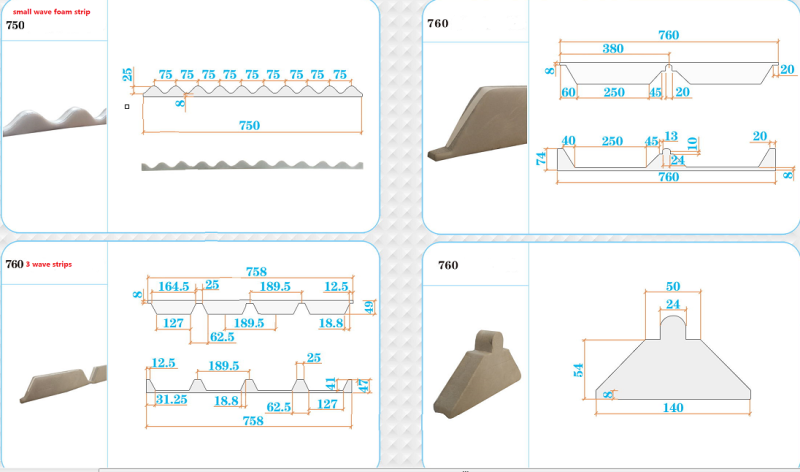

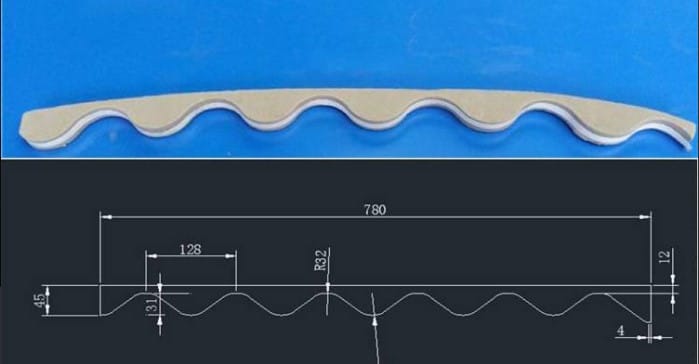

Dimension Of Foam Closure Strips

The sizes of foam closure strips mostly depends on the size of roofing panels. The regular length is around 36 inches, width 1 to 2 inches, thickness around 1 inches. Also different country uses corrugated roofing panel in different sizes and shapes. So the foam closure strips for different counties can be different in shapes and sizes.

How to choose

According to the drawing profiles, for example

Function:

1). Made of PEF material, thickness 25mm, color gray or white, large quantity can be customized, 780 big wave plug is a kind of wave shaped plug suitable for 780 color steel tile wall panel, cross-lap pressed metal plate, light weight, high strength, High rigidity, good waterproof and seismic performance;

2). The construction and installation are convenient, fast, and the construction period is short;

3). Good factory production quality;

4). The appearance is beautiful and novel, the colors are colorful, the decoration is strong, the combination is flexible and changeable, and different architectural styles can be expressed;

5). After the use of profiled steel plates as roofs and walls, it can reduce the material consumption of the load-bearing structure, reduce the installation and transportation workload, shorten the construction period, save labor, and have good overall economic benefits.

How to count

Two-sided sloping roof

Description of two-sided sloping roof

⒈The area of the roof: length×width.

⒉The total length of the required tile: roof area ÷ 0.855 (the effective width of the tile is 0.855M/piece).

⒊The number of tiles: (roof length÷0.855m)×2.

⒋The number of ridge tiles: roof length ÷ 2.4m (the effective length of ridge tiles is 2.4M/root).

⒌Number of sealing strips: (length ÷ 0.7m) × 2 (sealing strips 0.7M/piece).

⒍The number of the eaves cover: (length ÷ 0.7m) × 2 (the eaves cover 0.7M/piece).

⒎The number of nails: 4PCS/㎡.

⒏The roof angle is less than or equal to 120 degrees.

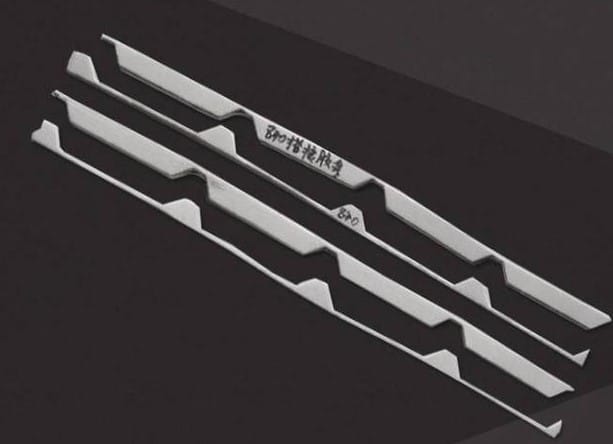

More types

More details

How to give accurate quotation

- Please show the drawing profile to match with.

- Tell us more details requirements of the color and thickness.

- The most important how much quantity you need.

More types for your reference: