The colored steel metal trapezoidal roof panel roll forming machine is a specialized mechanical equipment used for producing trapezoidal roof panels. It usually uses continuous forming technology to process colored coated steel plates or other types of metal plates into roof panels with specific corrugated shapes through processes such as pressing and shearing. The design of this machine not only produces trapezoidal roof panels with good waterproof performance, but also enhances the overall structural strength of the building.

Characteristics of Colored Steel Metal Trapezoidal Roof Panel Roll Forming Machine:

1.Automated production has improved production efficiency and reduced labor costs.

2. High precision molding process ensures the stability and consistency of product quality.

3. The equipment has a modular design, which facilitates equipment maintenance and updates.

4. It can achieve plastic molding in multiple colors to meet different design needs of customers.

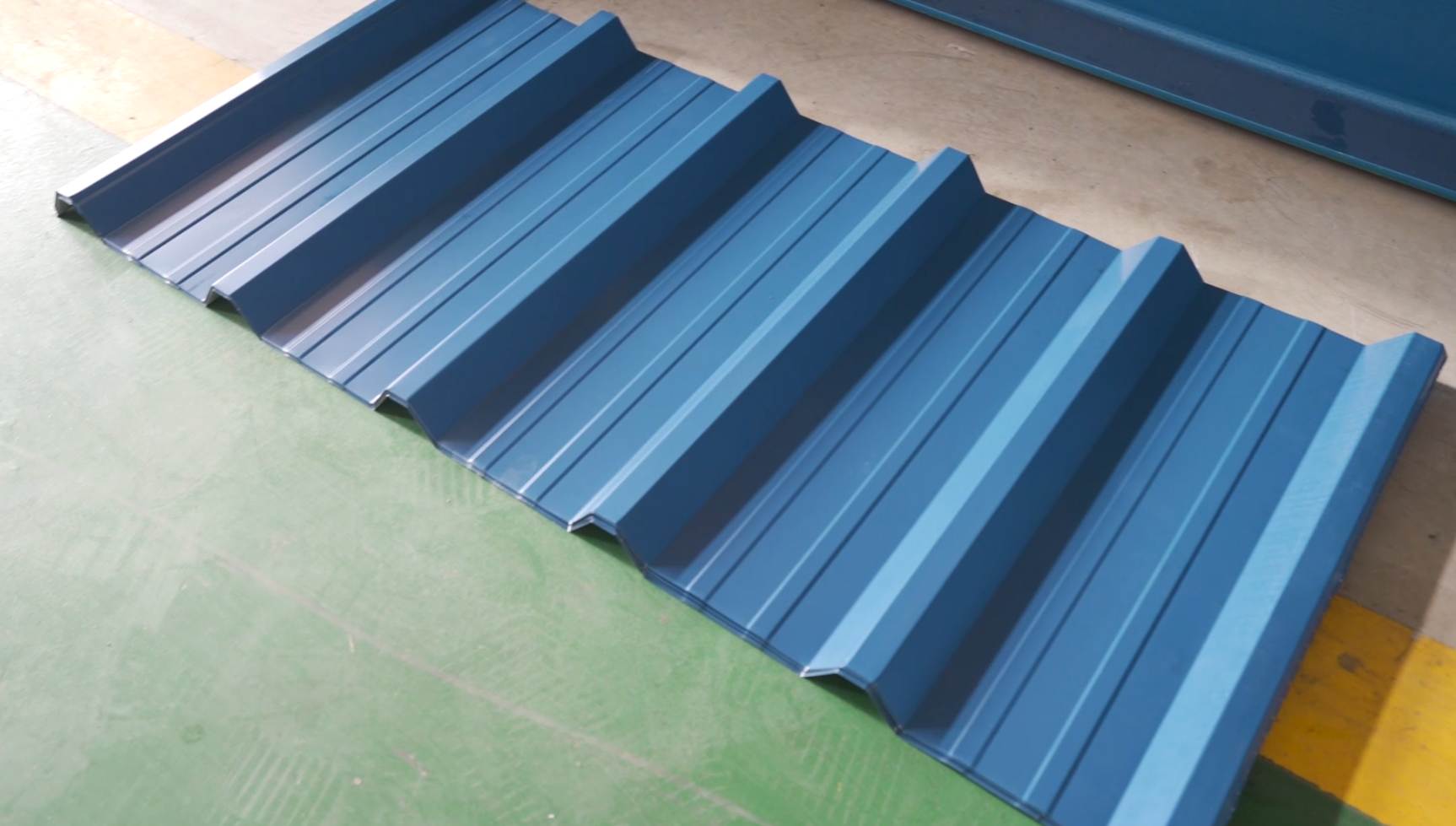

5. The trapezoidal color steel tiles produced have the characteristics of lightweight, high strength, waterproofing, and corrosion resistance, and are widely used in factories, large shopping malls, stations, sports venues, and other places.

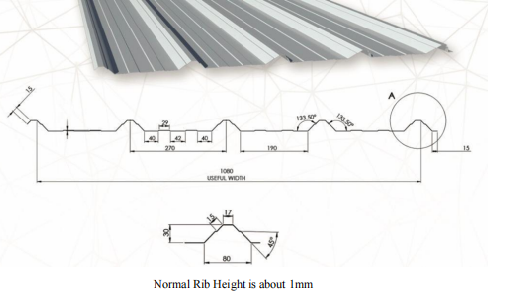

Pattern diagram:

Product Attributes :

1.Formed Material | PPGI,GI,AI | Thickness:0.3-0.8mm Width:1220mm/1450mm(customized as drawing) | ||

2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) | ||

3.Main body | Roller station | 20 rows(As your requirement) | ||

Diameter of shaft | 90mm solid shaft | |||

Material of rollers | 45# steel, hard chrome plated on the surface | |||

Machine body frame | 400 H steel | |||

Drive | Chain transmission | |||

Dimension(L*W*H) | 12500*1800*1600(customize) | |||

Weight | 10.5T | |||

4.Cutter | Automatic | cr12mov material, no scratches, no deformation | ||

5.Power | Motor Power | 7.5KW | ||

Hydraulic system power | 5.5KW | |||

6.Voltage | 380V 50Hz 3Phase | As your requirement | ||

7.Control system | Electric Box | Customized(famous brand) | ||

Language | English(Support multiple languages) | |||

PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |||

18.Forming Speed | 15-20m/min | The speed is adjustable | ||

Products Display:

Product Work Video:

No Comment

You can post first response comment.