Metal embossing machine is a device used for decorative treatments such as embossing and embossing on the surface of metal sheets, widely used in fields such as architectural decoration, furniture manufacturing, automotive interiors, and home appliance casings. The metal embossing machine applies pressure to the metal sheet through upper and lower embossing rollers, causing the metal sheet to undergo plastic deformation under pressure, thereby forming various pre designed patterns or textures. Embossing rollers are usually made of hard materials such as alloy steel and undergo heat treatment to improve wear resistance and hardness.

Main features:

- High precision and efficiency:

Metal embossing machines can accurately press complex patterns on metal sheets with high production efficiency. - Multifunctionality:

Suitable for various metal materials such as aluminum plates, stainless steel plates, galvanized plates, etc., it can meet the decoration needs of different industries. - Easy to operate:

Modern metal embossing machines are usually equipped with computer control systems, which are easy to operate and adjust. - Strong durability:

The embossing roller and machine frame are made of high-quality materials, with a long service life.

Application areas:

1.Architectural decoration:

used for producing decorative panels, curtain wall panels, etc., to enhance the aesthetic and artistic appearance of buildings.2.Furniture manufacturing:

Adding texture to the surface of metal furniture to increase the added value of the product.3.Automobiles and Home Appliances:

Used for surface decoration of automotive interior parts, home appliance shells, etc.Product Attributes :

1. Roller specifications: DIA450~500mm, width: 1000~2000mm.

2. Take the roll surface hard chromium plating

3. Suitable for pressing plate: 1-6 mm

4.Frame steel plate welded structure, polished, tempering, machining, solid wall plate Q235 90 mm thick

5. Pattern processed by laser engraving.

6. The pattern making: according to the buyer to provide the sample pattern

7. Pressure mode: hydraulic 50~100T.

8. Working speed: 0-10m/min, speed changed by frequency converter .

9. Voltage 380V/50Hz/3PH or customize

10. Safety shield shell

11. Beautiful appearance

Here is the working video of this machine for everyone to watch:

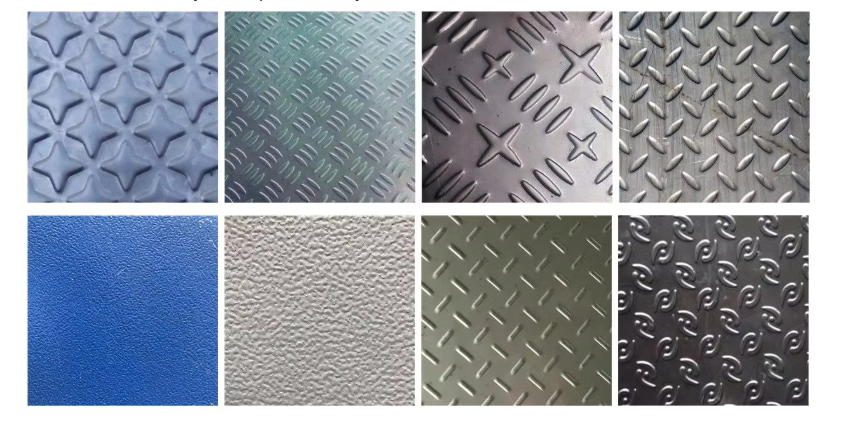

Products Display:

No Comment

You can post first response comment.