With the booming development of the Indonesian construction industry, especially the increasing demand for high-quality roofing materials in residential and commercial buildings, the market for glazed tile roofing sheet machines is showing a significant growth trend.

Description:

Material: colored steel plate, galvanized plate, or aluminum plate

Formed width:914mm

Material thickness:0.18-0.4mm

voltage:380V,50HZ

Technical features:

- Efficient production:

It can quickly and continuously press glazed tiles, greatly improving production efficiency and meeting the large demand for glazed tiles in the market. Compared with traditional handmade production, the output is significantly increased. - Accurate molding:

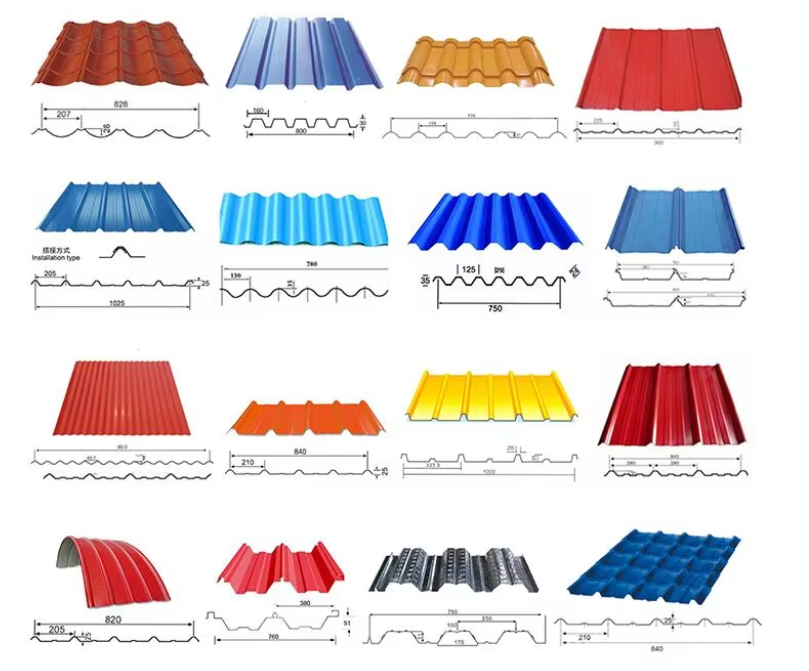

Glass tiles can be accurately pressed according to the preset size and shape, ensuring uniform tile specifications and minimal errors. The produced glass tiles have a neat and beautiful appearance, with good laying effects. - Strong applicability:

It can adapt to the production needs of various specifications and styles of glazed tiles. By adjusting molds and other methods, tiles with different curvatures, lengths, and widths can be produced, providing more choices for architectural design. - Reliable quality:

The equipment is made of high-quality steel and advanced technology, with a stable structure, durable components, stable operation, and can work continuously for a long time, reducing the frequency of failures and lowering maintenance costs.

Product Attributes :

| Item | Name | Specifications |

| 1 | Raw material | colored steel plate, galvanized plate, or aluminum plate |

| 2 | Raw material thickness | 0.18---0.4mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 10stations |

| 6 | Roller material | 45# steel, surface hard chromium plating. |

| 7 | Shaft diameter | 70mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 4kw |

| 11 | Machine frame | 350H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

Packing list :

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

No Comment

You can post first response comment.