Here is the working video of this machine for everyone to watch:

Product Attributes :

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.3---0.8mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 14stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 70mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 350H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 4.5kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

Product Description:

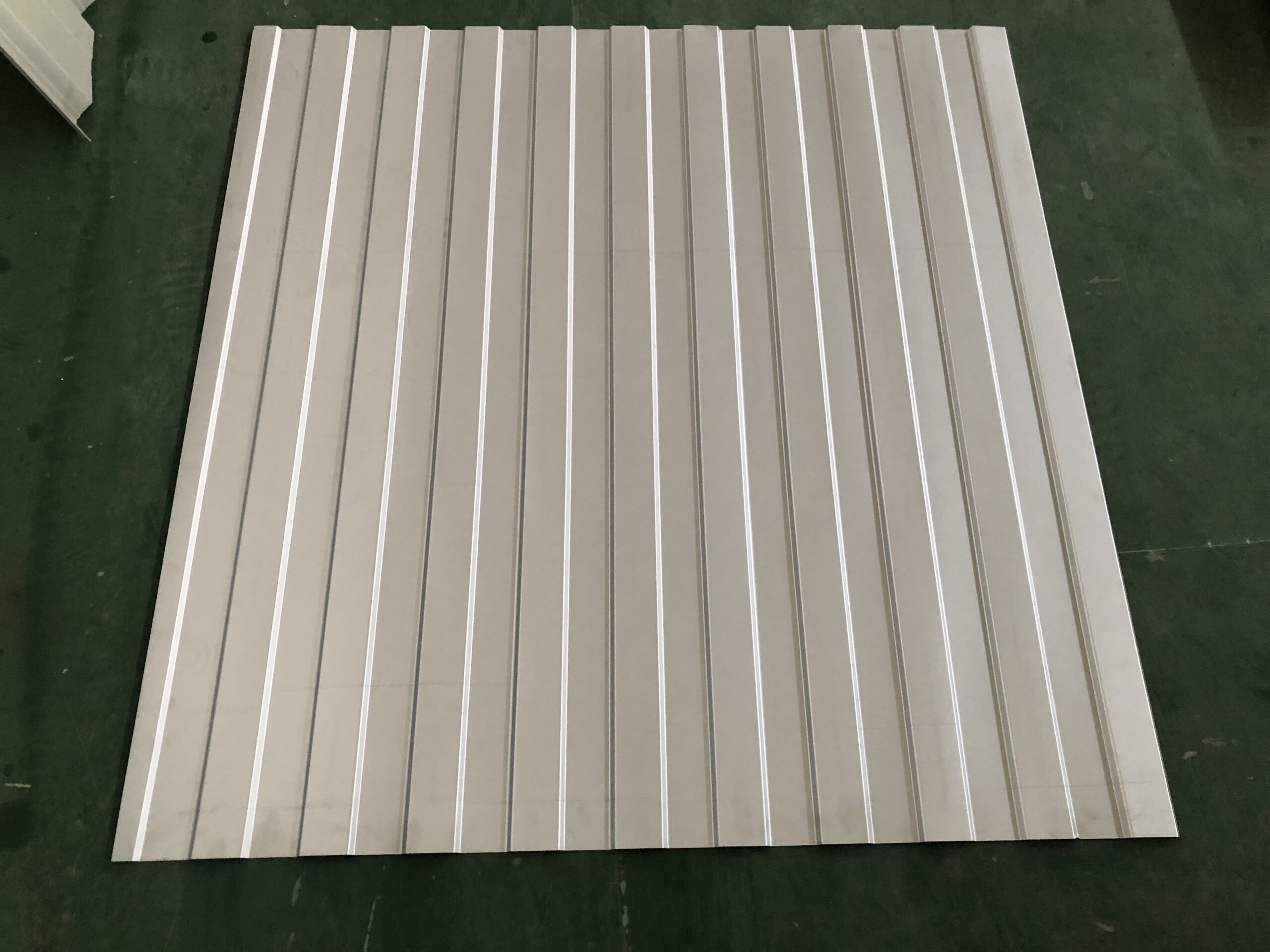

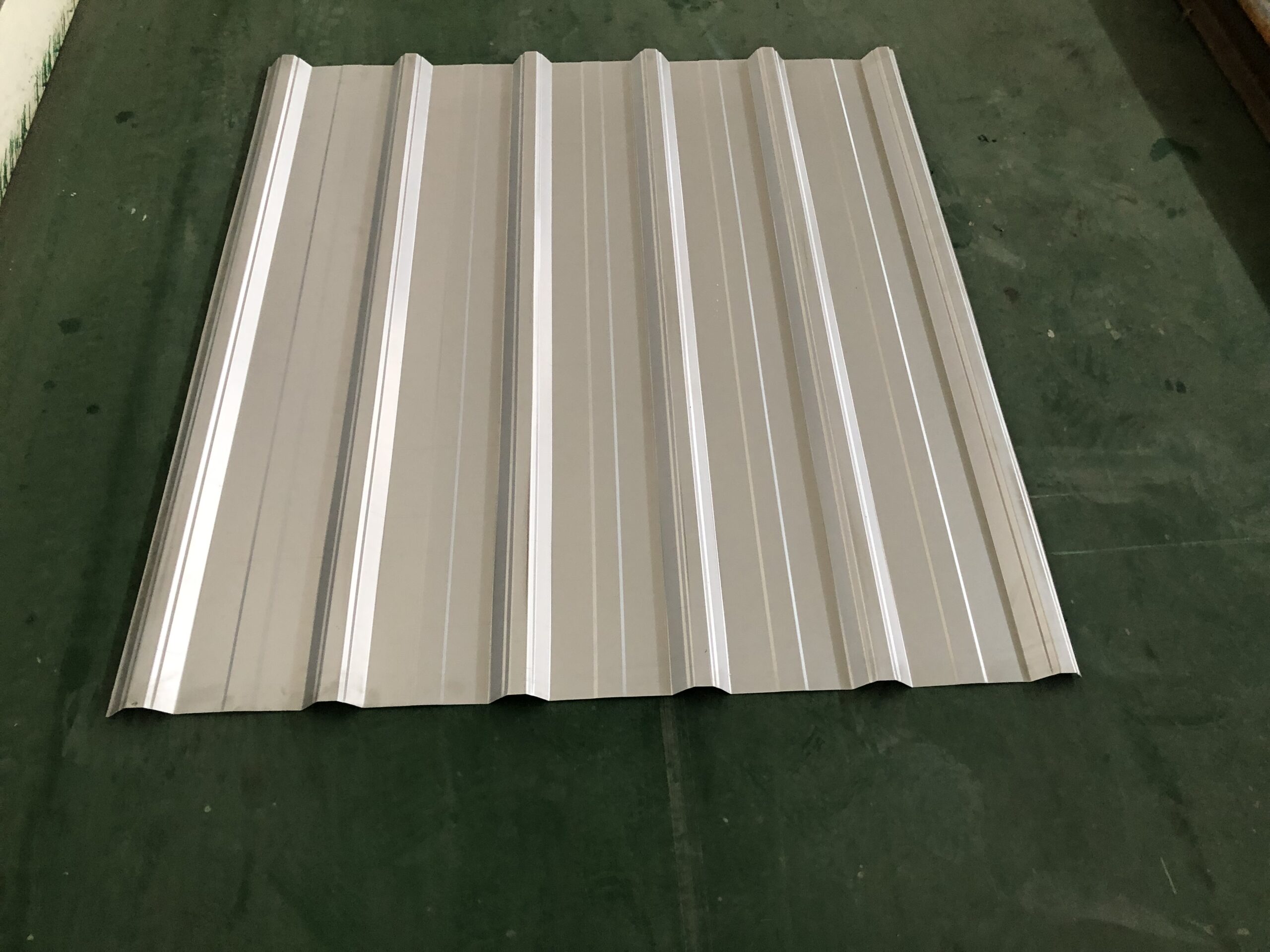

The double layer metal roll form tile making roof machine is an efficient and multifunctional building equipment, mainly used to process coil materials such as color coated steel plates and galvanized sheets into different cross-sectional shapes such as waves and trapezoids through roll forming technology. It has the unique advantage of being able to produce double-layer roof panels or wall panels with a single press, significantly improving production efficiency and material utilization. The double layer metal roll form tile making roof machine is widely used in industrial park buildings, factory buildings, logistics warehouses, and decorative cover plates on the roofs of private residential houses.

Main advantages:

1.Efficient production:

capable of simultaneously pressing two layers of color steel plates, greatly improving production efficiency and reducing production costs. This design enables the production of more color steel tile products at the same time, meeting the needs of large-scale production.

2.Economical:

Combining two types of equipment into one making roof machine not only saves space, but also significantly reduces equipment costs. Compared to using two single-layer tile presses, double-layer tile presses have lower costs and are suitable for users with limited budgets.

3.Automation and Intelligence:

Typically equipped with advanced control systems, it can achieve precise positioning, automatic feeding, continuous pressing, and other functions, reducing manual intervention and improving production accuracy and safety. In addition, the operation and maintenance of the equipment are relatively simple, reducing labor costs.

4.Multifunctionality:

The mold design of the multifunctional double-layer tile press is flexible and diverse, and different shapes and specifications of tile shapes can be customized according to customer needs to meet the diversified needs of the market. This flexibility enables the equipment to play an important role in various construction projects.

5.High quality products:

Color steel tiles have the characteristics of lightweight, high strength, corrosion resistance, easy processing, and beauty, and are suitable for multiple fields such as roofs, walls, partitions, and temporary buildings. Its appearance is flat, with uniform ripples and high utilization rate, which can meet the needs of various buildings.

No Comment

You can post first response comment.