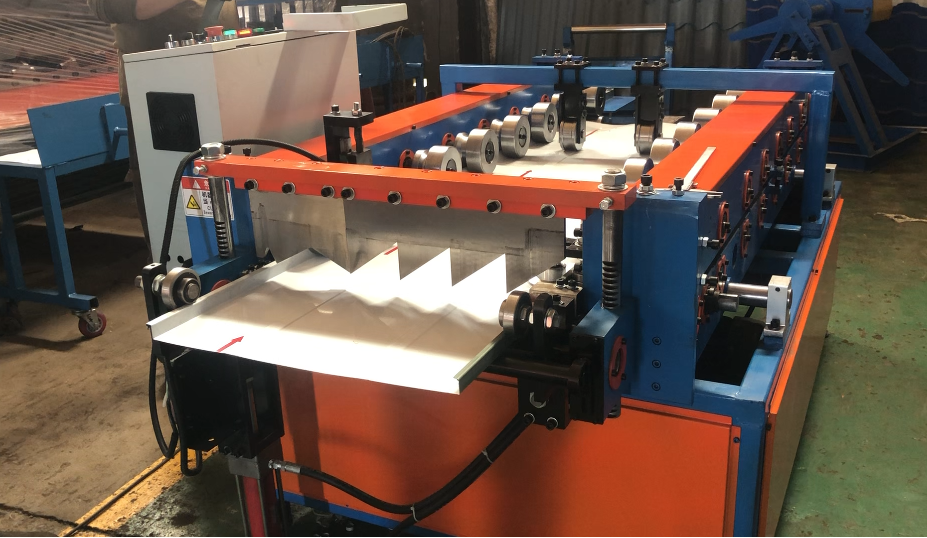

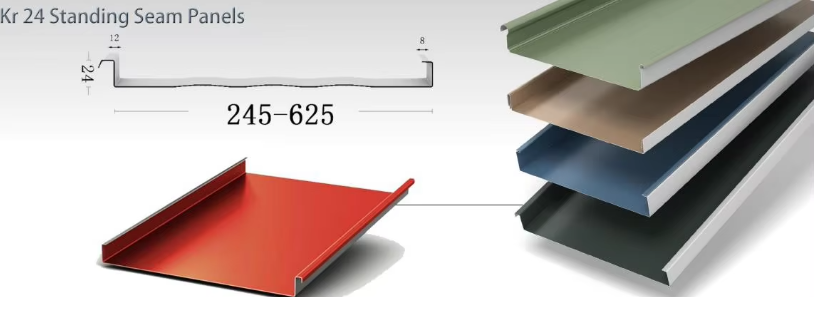

The portable standing seam roof sheet roll forming machine is a device with simple structure, small volume, and small footprint, suitable for on-site production of various sizes of roof tiles, reducing transportation costs and material waste. The equipment mainly includes a frame, a guiding feeding mechanism, a roll forming mechanism, and a hydraulic shearing mechanism. A linear guide is installed above the frame, and the fixed side roll forming mechanism and the moving side roll forming mechanism are connected to the transmission gear through gear shafts. The moving side roll moves on the linear track through a slider and is controlled by a transverse motor.

Application scenarios and advantages:

The portable standing seam roof sheet roll forming machine is suitable for on-site production of roof tiles of various sizes, especially for scenarios that require quick installation and reduced transportation costs. Its simple structure, small size, and small footprint make operation and maintenance relatively simple, suitable for the needs of various engineering projects. In addition, the device also has efficient and stable production capacity, which can ensure the reliable quality of the produced roof tiles and meet the needs of various specifications and shapes.

Characteristics of the machine:

- Portability:

The portable vertical seam roof tile machine is designed to be compact, easy to move and transport, and suitable for quick transfer and use between different construction sites. - Intelligent operation:

adopting advanced control systems such as PLC control, easy to operate, suitable for large-scale production and remote monitoring. - Waterproof and thermal insulation performance:

Roof tiles have good waterproof and thermal insulation performance, which can effectively reduce air conditioning load and are suitable for use in rainy and high-temperature areas.

Product Attributes :

Parameter and Performance | Suitable material | PPGI, GI, Aluminium etc |

Material thickness | 0.3-0.8mm | |

Main components | decoiler, Roll forming machine, PLC control system, Hydraulic station | |

Production speed | 12-35m/min( speed adjustable) | |

Feature | Main frame:350-500H beam Steel PLC: Delta or Siemens (or as your request) Touch screen langauge: English/Chinese/as your request Roller material: high grade 45# steel with hard chrome coated Shaft material: 45# steel, solid Cutting: Hydraulic cutting system The unique feed inlet design can protect the coil paint surface and prolong the service life of roof tiles. The cooling system on the hydraulic station can avoid overheat of hydraulic oil after long-time operate, ensure provide enough power. |

No Comment

You can post first response comment.