描述

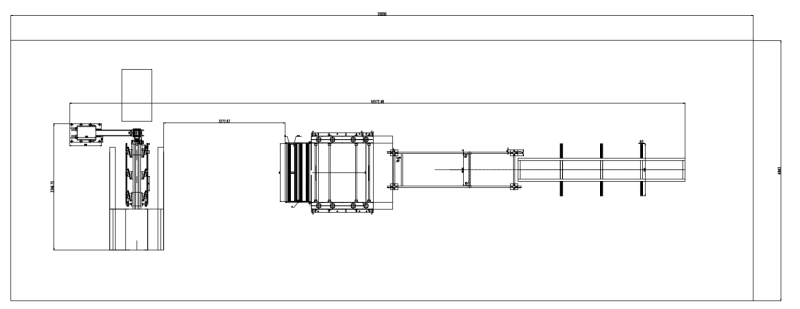

Simple Cut to Length Line

The simple cut to length line is specially designed for low capacity but economical investment. It is developed from ordinary transversal cutting machines, but retains their functions and simplifies the structure to lower cost. This line is also known as simple cut-to-length production line. It is typically used for small slitting demand. Customers often use this simple cut to length line to slit coil for own use rather than for external processing service.

Working Process of Simple Cut-to-Length Production Line

Hydraulic decoiler -Feeding roller- Leveling rollers - Cutting device- convey - automatic stacker

Technical Parameters of Simple Cut to Length Line

| Item | Parameters | Remark | |

| Material | Raw material | Color sheet and galvanized plate | |

| Yield Strength (Mpa) | 230 to 300 | ||

| Thickness (mm) | 0.3 mm to 1.0 mm | ||

| Slitting Width (mm) | 80mm to 1250 mm | ||

| Working Speed (m/min) | about 15 m/min | ||

| Slitting Blade | 6 pcs | 1pc as spare part | |

| Main Motor Power (KW) | 2.2 | depend on final design | |

| Hydraulic Motor Power (KW) | 5.5 | depend on final design | |

| Total Power | 7.7 | depend on final design | |

| Dimension (L × W × H) (m) | 12 × 3 × 2 | depend on final design | |

Structure Components of Simple Cut-to-Length Production Line

| Name | Description | Qty | Technical Details |

| Decoiler | Passive Decoiler | 1set | arm type, hydraulic expanding, passive decoiling |

| Main System | Feeding Guide Device | 1set | 1. Roll inner supporting structure type: column 2. Motor driving, the back/forward rollers driven by chain, part of upper/lower rollers driven by gear 3. Cutting blade material Cr12 quenched treatment 4. Slitting blade material Cr12 quenched treatment 5. Roll conveyor adopts 4 group rubber rollers. |

| Film System | 1 set | ||

| Roller Conveyor | 1set | ||

| Cutting Device | 1set | ||

| Slitting Device | 1set | ||

| Supporting Table | Supporting Table | 1set | Support finished products. Length will be 4 m. |

| Hydraulic System | 1set | Main machine and decoiler uses inside-placed and separated hydraulic station. | |

| Electric System | 1set | 1. PLC Control, encoder automatic cutting in length 2. Operation mode: touch screen and button 3. Adjust the speed by AC frequency conversion. | |